China Supplier Compression Screw - Moving Screw Motor And Sliding Rail Motor – Jieyi

China Supplier Compression Screw - Moving Screw Motor And Sliding Rail Motor – Jieyi Detail:

Details

Processing customized:YES.

Item no: FS-0000-M.

Model: Horizontal slip motor.

Type: micro motor.

Applicable models: various models.

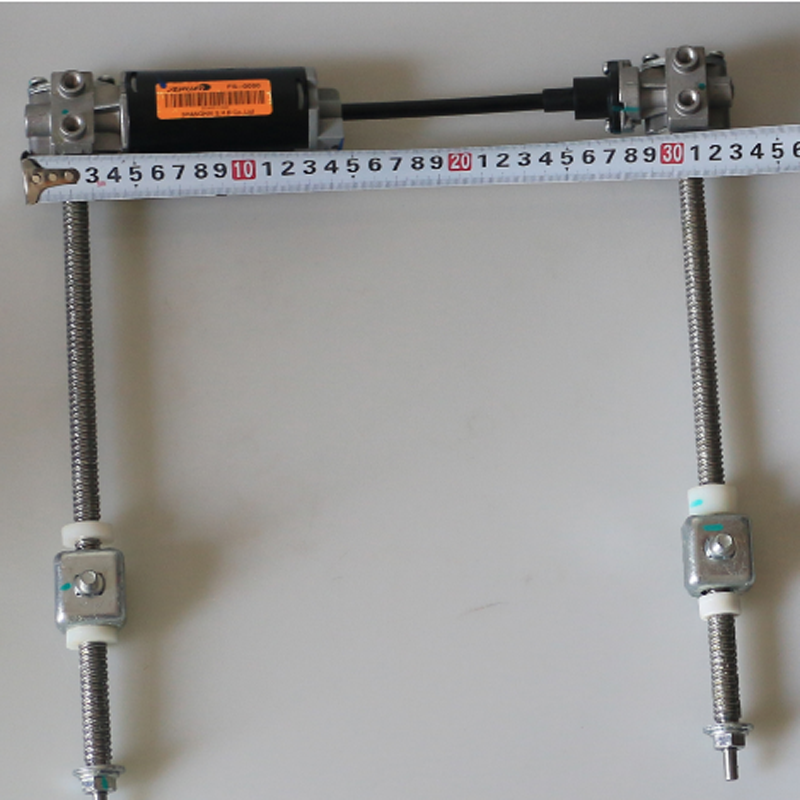

Appearance size: Φ40*160*200.

Origin: China.

Material: iron.

Raise the distance: 30CM.

|

model |

voltage(V) |

no-load |

blocked |

noise |

brand |

weight |

|||

|

Range |

lines |

speed(rpm) | current(A) |

torque |

current(A) | ||||

|

Horizontal slip motor |

9-13 |

13 |

185-230 |

2.5 |

4.95-7.5 |

25 |

≤42 |

JIEYI |

496 g |

Why Choose Us

Choose us, and you’ll never have these problems again. Four advantages, give you a different temperament

- power foot: pure copper wire rotor

- low noise: low noise when lifting

- long life: long service life

- good material: selected high-quality materials

Adjustment

front and back stroke adjustment

“Worm gear screw mechanism, the screw is fixed on the sliding rail, the worm wheel is fixed on the upper slide rail, the motor drives the worm wheel or screw rotation through the hose drive into the upper slide rail moves forward and backward along the screw.”

seat up and down stroke adjustment

The lifting of the seat is divided into integral lifting and separate lifting before and after as well as the front part of the lifting, in fact, the principle is the same.

(1) Worm gear lead rod, lead rod on the motor, motor and worm gear respectively with four connecting rod at both ends of the rotary connection.

The linear movement of worm gear on the screw is transformed into the overall movement of the four-link, which drives the seat to move up and down.

(2) Gear movement

The fan-shaped tooth plate is connected as the driving end (rear beam) of the four connecting rods.

The gear on the motor drives the rotation of the fan-shaped tooth plate, so as to drive the movement of the four connecting rods and realize the lifting and lifting of the seat.

back and back Angle adjustment

In simple terms, the Angle of the backrest adjustment is done by mediator plate, and illustrates disc is two main gear plate of crank, eccentric CAM driven rotary motion between outer teeth plate, the number of teeth on the tooth plate and the inner gear plate outside one tooth difference, between the external gear plate, gear plate rotation is formed a tooth differenced planetary gear pair.

Other Customized Products

Product Size

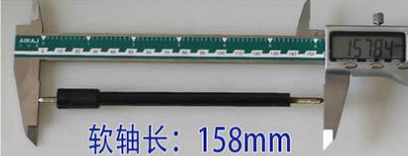

Product detail pictures:

Related Product Guide:

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for China Supplier Compression Screw - Moving Screw Motor And Sliding Rail Motor – Jieyi, The product will supply to all over the world, such as: Gambia, Guinea, Armenia, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.